- 800-769-8620

- | Home

- | About NDSI

- | Contact Us

- | Employment

- | Client Login

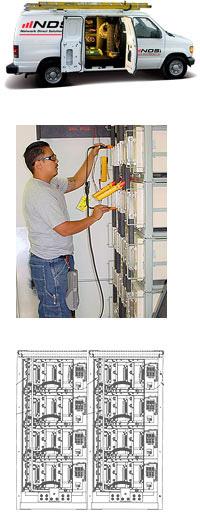

| Battery systems that are properly maintained by qualified power specialists will operate with optimized performance. We have the experience, training, and special tools required to perform all of your maintenance needs. We follow a rigorous process recommended by IEEE Std. 1188 for a high level of support you can depend on. |

We have experience supporting critical installations across a broad range of applications: |

|

NDSI strictly follows the guidelines of IEEE Std. 1188. Scheduled maintenance and records of each service can expedite resolution of any warranty claims. |

| 1. Initial Inspection After the battery has been on float for one week, the following data and information will be recorded: |

|

| 2. Monthly Inspection The following are checked as part of our monthly inspection: |

|

| 3. Quarterly Inspection The following items are checked on a quarterly basis, in addition to the monthly inspection items: |

|

| 4. Annual Inspection The following items are checked on a yearly basis, in addition to the monthly and quarterly items: |

|